Why Plastic Protective Film is a Must-Have

Plastic protective film is indispensable for safeguarding delicate surfaces during manufacturing, transportation, and application processes. Whether you’re protecting metal panels, glass, or furniture finishes, the right protective film ensures durability, efficiency, and customer satisfaction.

The Importance of Using Plastic Protective Film

- Preserve Surface Integrity:

Protect high-value materials like glass, stainless steel, and composite panels from scratches, dents, and stains during handling and installation. - Prevent Costly Replacements:

Damaged surfaces often lead to reworks or replacements, adding unnecessary costs to projects. A high-quality protective film mitigates these risks. - Boost Efficiency:

Using films tailored to specific applications minimizes time spent cleaning or repairing, keeping projects on schedule. - Enhance Customer Satisfaction:

Delivering damage-free materials enhances trust and strengthens your reputation.

Applications of Plastic Protective Film

- Construction Materials:

Safeguard decorative surfaces like aluminum panels, glass, and marble from scratches and debris on construction sites. - Automotive Industry:

Protect painted surfaces, dashboards, and trims during production and transportation. - Furniture Manufacturing:

Prevent damage to polished wood, acrylic, or laminated surfaces during storage or assembly.

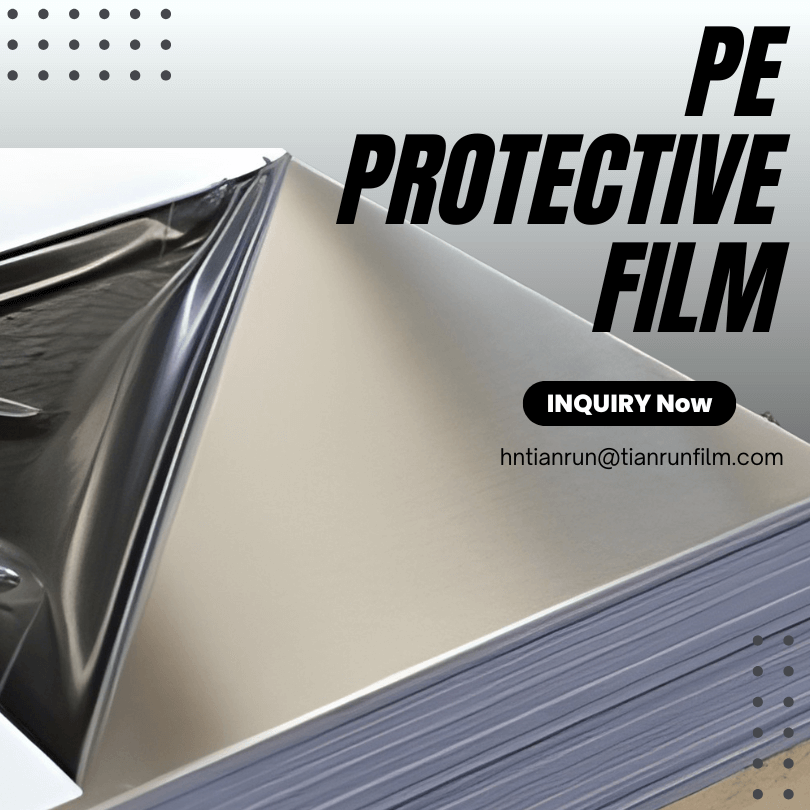

Features of Tianrunfilm’s Plastic Protective Film

Strong Adhesion with Easy Removal:

Ensures the film stays in place without leaving residue.

- Customized Specifications:

Available in varying thicknesses, widths, and adhesive strengths tailored to specific needs. - Eco-Friendly and Durable Materials:

Made with 25% LDPE and water-based adhesives from top suppliers like PetroChina, reducing environmental impact without compromising performance. - Transparent and Printable Options:

Branding and instructional prints are available for enhanced usability.

Common Issues and Tianrunfilm’s Solutions

- Adhesion Problems:

Films are rigorously tested to match the surface energy of different materials, ensuring a perfect bond. - Residue on Removal:

Advanced adhesive formulations prevent residue, even after extended application periods. - Tearing or Wrinkling:

Reinforced films resist tearing during transportation or handling. - Environmental Sensitivity:

Our films perform well under diverse conditions, from high humidity to extreme temperatures.

Why Choose Tianrunfilm

- State-of-the-Art Manufacturing:

Advanced three-layer co-extrusion ensures uniformity and reliability. - Certifications and Compliance:

ISO-certified processes and ROHS compliance guarantee quality and safety. - Comprehensive Customer Support:

From product selection to post-delivery support, we ensure smooth experiences at every stage.

Need Help Choosing the Right Protective Film?

Let our team guide you in selecting the ideal plastic protective film for your project. Explore our catalog or contact us today for tailored solutions!